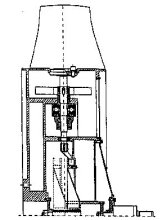

Variable pitch in motion

History

There are many applications where it is required to adapt the volume flow rate (reducing or increasing) according to the changing values of the process.

Some decades ago, when electronic speed control was in its infancy, the volume flow rate was adjusted as follows:

- By a damper (cheap solution, very low overall efficiency),

- With an adjustable DC motor (very expensive motors and control units) or

- By impellers with variable pitch angle in motion (mechanically very complicated, acceptable efficiency).

Advantages of variable pitch in motion

For only very few applications do axial fans with variable pitch in motion have the following advantages:

- Possibly a little better efficiency with non-quadratic system resistance-curve (example: mine-ventilation with weekly lengthening tunnels).

- No additional electrical losses (1 − 2%) by the operation with a frequency converter.

- Extremely high demands for an electromagnetic compatibility (no examples known − even in military submarines the use of frequency converters is allowed)

Disadvantages of variable pitch in motion

- High capital expenditure, as technically/structurally very complicated.

- Low safety in operation, as the failure of many small components easily can lead to a failure of the whole fan unit.

- Very high maintenance costs because of numerous mechanic wear and tear parts (bearings of the blades etc.).

- Very high risk of a "stall", as with a wrong pitch adjustment the fan will inevitably go into stall (= burble).

- Parallel operation very complicated, as a pumping (hunting) between two fans can be avoided only by using a very complex system control.

- Heat resistance very problematic, as combustible hydraulic oil is used. The whole hydraulic unit (also at the impeller) has to be thermically insulated. Varying the pitch in motion (forward, reverse, etc.) in a fire situation mostly not possible.

- For a quadratic system resistance curve (which is the most common one) optimum efficiency is only reached at one single working point, in all other working points lower efficiencies than frequency converter driven fans with fixed blades.

Conclusion

- Except for a very small advantage in efficiency in some applications, fans with variable pitch in motion give no relevant advantages. Therefore nowadays these fans present an out-dated technology, which is only used for special applications (e.g. mines). The production of this kind of fan has nearly discontinued in Germany.

- From an economical point of view fans with variable pitch in motion are too expensive to purchase and maintain compared with frequency converter driven fans with fixed blades.

- From a safety aspect fans with variable pitch in motion are to be classified much lower than frequency converter driven fans with fixed blades.

- All modern frequency converters can be equipped with network-filters and chokes to realise very high electromagnetic compatibility.