Energy Efficiency (EcoDesign)

Requirements

The EU aims to save energy. This is legislated for in the „Ecodesign Directive“ (or „ErP“ [Energy-related Products] Directive 2009/125/EC of the European Parliament.) This replaces the old “Ecodesign directive 2005/32/EC”, which was also called EuP Directive [Energy-using Products]. In Germany this has been implemented in the “Gesetz über eine umweltgerechte Gestaltung energiebetriebener Produkte” Energiebetriebene-Produkte-Gesetz-EBPG. The principles behind the directive have been further clarified by the EU in the “Blue Guide 2014”.

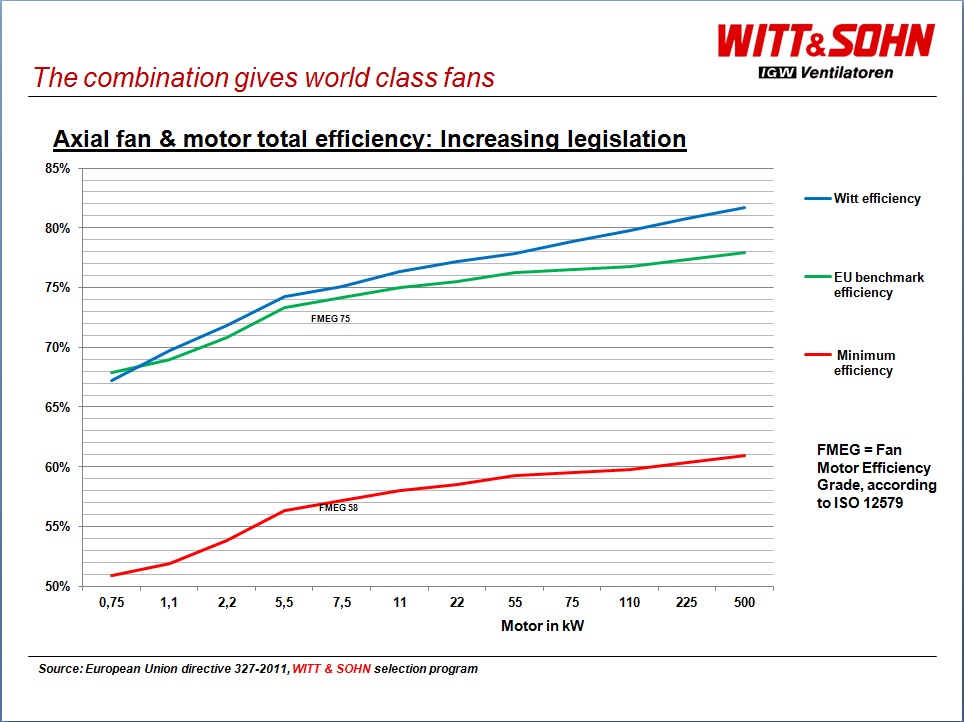

For different types of products than those covered by the above directive, further directives have been issued. For fans this is the EU directive No. 327/2011: “European requirements for fans drive by motors with an electric input power between 125 kW and 500 kW” issued in March 2011.

The basis for this directive was developed by the fan industry and issued as an ISO-standard 12579: Fans-Efficiency classification for fans.

Since all fans falling under the directive 327/2011 are driven by electrical motors, the Ecodesign directive for electrical motors EU 640/2009 is also important. This directive is based on the EU-standard 60034-30:2009 which for fans is based on IEC: 60034-30:2008 “Rotating electrical machines - Part 30: Efficiency classes of single-speed, three phase, cage-induction motors”.

Both directives regulate the requirements for fans with electrical motors in terms of market introduction and usage of the products.

The cornerstones of the directives are:

A. EU 327/2011: Fans

- Valid for axial fans, centrifugal fans, mixed flow fans and cross flow fans.

- The electrical input power of the motors is between 125 kW and 500 kW.

- The directive sets minimum requirements for the combined electrical efficiency of fan and motor.

- There are a number of exceptions such as atex fans, fans for use in toxic, corrosive or abrasive environments, high temperature etc.

- The first stage of the directive came into force 01.01.2013. A second stage with the same content, but with higher limit values came into force on 01.01.2015.

Further details can be found in our presentation in the Know-How-Centre:

B. EU 2019/1781 from 01.10.2019 - Electrical motors

Definition:

- A single-speed three-phase 50-Hz or -50/-60-Hz-squirrel cage introduction motor

- 2- to 8-pole

- Rated voltage up to 1000 V

- Rated power from 0.12 kW to 1000 kW

- Designed for continuous operation

Exceptions

The regulation 2019/1781 does not apply to motors:

- Which are fully submerged into liquid.

- Which are integrated completely into a product so that energy efficiency can only be determined for the total product.

- Over 4000 m above sea level.

- For ambient temperature above 60°C.

- For maximum operating temperatures above 400°C.

- For ambient temperatures below -30°C (any type of motor) or below 0°C (water-cooled motor only).

- Cooling temperature at the inlet of a product below 0°C or above 32°C.

- In hazardous areas according to directive 94/9/EC (ATEX).

- For brake motors.

- for motors with integrated speed controls.

Requirements

- From 16.06.2011 motors must have at least efficiency class IE2.

- From the 01.01.2015 motors from 7.5 to 375 kW must have

- at least efficiency class IE3

- or efficiency class IE2 in combination with a speed control

- From the 01.01.2017 motors from 0.75 to 375 kW must have

- at least efficiency class IE3

- or efficiency class IE2 in combination with a speed control.

- From 01.07.2021, electric motors between 0.75 and 1000 kW

- must achieve at least the IE3 efficiency level.

- Motors between 0.12 kW and 0.75 must achieve IE2.

- From 01.07.2023, electric motors between 0.75 and 200 kW

- must achieve at least the IE4 efficiency level.

- Ex-eb motors between 0.12 and 1000 kW must achieve IE2.

| Class | Description | Origin |

|---|---|---|

| IE1 | Standard | 50Hz: old EFF2 class as CEMEP-EU 60Hz: identical to Brazilian standards |

| IE2 | High | old EFF1 class to CEMEP-EU 60Hz: same as U.S. American EPACT |

| IE3 | Premium | 15% - 20% reduction in losses compared with IE2 60Hz: same as U.S. American EPACT |

| IE4 | Super-Premium | for future highly-efficient motors |

| IE... |

For the Witt & Sohn relevant product groups of axial and centrifugal fans from 0,75 kW to 500 kW, our products not only fulfill all requirements, but even surpass the bench marks identified by the EU.

Witt has outperformed the ErP2015 for years!